For this application, I use Omron PLC CP1L with external

analog input and digital output as digital battery level indicator with 4 levels

for 6 volt battery.

C. 6 volt and 4 levels battery indicator to digitized

Download PLC Program File: Click Here

F. Video about make ladder program for Battery Level Indicator

See the video for this application:

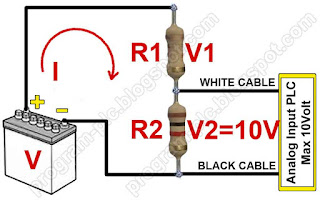

A. Wiring

Diagram between Battery, Analog Input PLC, and Digital Output PLC of Omron PLC

CP1L

A.1.Preparation

1. Omron PLC CP1L-L10 with external analog input

2. External Analog

Cable

Remarks:

Black color to negative battery

White color to positive batteryy

3. Battery DC 6 Volt for Testing

For this application, I use battery dc 1.5 volt as

many as 4 pieces.

A.2. Installation

1. Battery to Analog

Input PLC

2. Accumulator to Analog Input PLC

B.

Information about External Analog Input of Omron PLC CP1L

Analog voltage values 0 volts to 10 volts can be

digitized with 0 to 255. Digitized values are sent to the A643 of Omron PLC CP1L.

The following is relationship between Voltage Values and A643.

C. 6 volt and 4 levels battery indicator to digitized

The following descriptions:

1.

10 Volt digitized = 255

2. 6

Volt digitized = (255/10) X 6 = 153

3. 6

Volt per 4 Levels (Per Level) digitized = 153/4 = 38.25

In PLC Programming: Because per Level there is 2 digits after

point, and then 153 multiplied by 100. And Value for per Level = (153 X 100) /

4 = 15300 / 4 = 3825 (this value no point and suitable for PLC programming)

4. The values of each level become:

4. a. Level 1: (153 X 100)/4 = 3825 is the digital

value of analog 1.5 Volt of battery

4. b. Level 2: (153 X 100)/3 = 7650 is the digital

value of analog 3 Volt of battery

4. c. Level 3: (153 X 100)/2 = 34425 is the digital

value of analog 4.5 Volt of battery

4. d. Level 4: (153 X 100)/1 = 15300 is the digital

value of analog 6 Volt of battery

5.

PLC Programming for per levels of Battery Level Indicator

5. a. BufferA643 = A643 X 100

5. b. Level 1: If (BufferA643) >= 3825) Then Digital

Output 100.00 = ON

5. c. Level 2: If (BufferA643) >= 7650) Then Digital

Output 100.01 = ON

5. d. Level 3: If (BufferA643) >= 34425) Then Digital

Output 100.02 = ON

5. e. Level 4: If (BufferA643) >= 15300) Then Digital

Output 100.03 = ON

The following is relationship between battery level

indicator and Digital Value (A643) of Omron PLC CP1L.

D. Digital Output

Light Lit for each Level

E. Ladder Program for Battery Level Indicator

F. Video about make ladder program for Battery Level Indicator

G. For other

battery voltage

Battery voltage greater than 10 volt should use

additional resistors, e.g. 12VDC, etc.

In this case use Kirchhoff's Voltage Law (KVL), See

the picture below:

Example

Battery Voltage (V) =12volt

Defined:

V=12 volt

R2=1000 ohm

V2=10 volt

Then:

I=V / (R1+R2)

I=V2/R2

V2/R2 =V / (R1+R2)

V2(R1+R2)=V*R2

V2*R1+V2*R2=V*R2

V2*R1=V*R2 – V2*R2

R1=

((V-V2)*R2)/V2

R1=((12-10)*1000)/10

R1=2000/10

R1=200 ohm

Watt Resistor (Standards: 1/8W, 1/4W, 1/2W, etc.)

I=V/(R1+R2)

I=12/(200+1000)

I=0.01A

Watt R1=I*I*R1=0.01*0.01*200

= 0.02watt = 1/8W

Watt R2 =I*I*R2=0.01*0.01*1000=0.1watt

= 1/4W

For Battery Voltage=12volt uses R1=200 ohm 1/8W and

R2=1000 ohm 1/4W

For other battery voltage, you can try with way the

above.