Introduction

Connecting external devices to a PLC controller regardless whether they are input or output is a special subject matter for industry. If it stands alone, PLC controller itself is nothing. In order to function it needs sensors to obtain information from environment, and it also needs execution devices so it could turn the programmed change into a reality. Similar concept is seen in how human being functions. Having a brain is simply not enough. Humans achieve full activity only with processing of information from a sensor (eyes, ears, touch, smell) and by taking action through hands, legs or some tools. Unlike human being who receives his sensors automatically, when dealing with controllers, sensors have to be subsequently connected to a PLC. How to connect input and output parts is the topic of this chapter.

Sinking-Sourcing Concept

PLC has input and output lines through which it is connected to a system it directs. Input can be keys, switches, sensors while outputs are led to different devices from simple signalization lights to complex communication modules.

This is a very important part of the story about PLC controllers because it directly influences what can be connected and how it can be connected to controller inputs or outputs. Two terms most frequently mentioned when discussing connections to inputs or outputs are "sinking" and "sourcing". These two concepts are very important in connecting a PLC correctly with external environment. The most brief definition of these two concepts would be:

SINKING = Common GND line (-)

SOURCING = Common VCC line (+)

First thing that catches one's eye are "+" and "-" supply, DC supply. Inputs and outputs which are either sinking or sourcing can conduct electricity only in one direction, so they are only supplied with direct current. According to what we've said thus far, each input or output has its own return line, so 5 inputs would need 10 screw terminals on PLC controller housing. Instead, we use a system of connecting several inputs to one return line as in the following picture. These common lines are usually marked "COMM" on the PLC controller housing.

Input lines

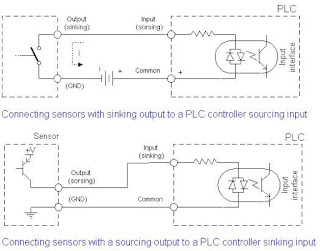

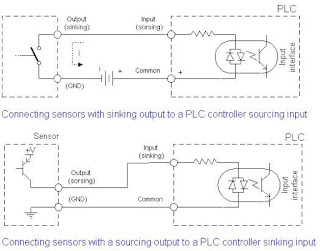

Explanation of PLC controller input and output lines has up to now been given only theoretically. In order to apply this knowledge, we need to make it a little more specific. Example can be connection of external device such as proximity sensor. Sensor outputs can be different depending on a sensor itself and also on a particular application. Following pictures display some examples of sensor outputs and their connection with a PLC controller. Sensor output actually marks the size of a signal given by a sensor at its output when this sensor is active. In one case this is +V (supply voltage, usually 12 or 24V) and in other case a GND (0V). Another thing worth mentioning is that sinking-sourcing and sourcing - sinking pairing is always used, and not sourcing-sourcing or sinking-sinking pairing.

If we were to make type of connection more specific, we'd get combinations as in following pictures (for more specific connection schemas we need to know the exact sensor model and a PLC controller model).

Output lines

PLC controller output lines usually can be:

-transistors in PNP connection

-transistors in NPN connection

-relays

The following two pictures display a realistic way how a PLC manages external devices. It ought to be noted that a main difference between these two pictures is a position of "output load device". By "output load device" we mean some relay, signalization light or similar.

How something is connected with a PLC output depends on the element being connected. In short, it depends on whether this element of output load device is activated by a positive supply pole or a negative supply pole.

author: Nebojsa Matic

Connecting external devices to a PLC controller regardless whether they are input or output is a special subject matter for industry. If it stands alone, PLC controller itself is nothing. In order to function it needs sensors to obtain information from environment, and it also needs execution devices so it could turn the programmed change into a reality. Similar concept is seen in how human being functions. Having a brain is simply not enough. Humans achieve full activity only with processing of information from a sensor (eyes, ears, touch, smell) and by taking action through hands, legs or some tools. Unlike human being who receives his sensors automatically, when dealing with controllers, sensors have to be subsequently connected to a PLC. How to connect input and output parts is the topic of this chapter.

Sinking-Sourcing Concept

PLC has input and output lines through which it is connected to a system it directs. Input can be keys, switches, sensors while outputs are led to different devices from simple signalization lights to complex communication modules.

This is a very important part of the story about PLC controllers because it directly influences what can be connected and how it can be connected to controller inputs or outputs. Two terms most frequently mentioned when discussing connections to inputs or outputs are "sinking" and "sourcing". These two concepts are very important in connecting a PLC correctly with external environment. The most brief definition of these two concepts would be:

SINKING = Common GND line (-)

SOURCING = Common VCC line (+)

First thing that catches one's eye are "+" and "-" supply, DC supply. Inputs and outputs which are either sinking or sourcing can conduct electricity only in one direction, so they are only supplied with direct current. According to what we've said thus far, each input or output has its own return line, so 5 inputs would need 10 screw terminals on PLC controller housing. Instead, we use a system of connecting several inputs to one return line as in the following picture. These common lines are usually marked "COMM" on the PLC controller housing.

Input lines

Explanation of PLC controller input and output lines has up to now been given only theoretically. In order to apply this knowledge, we need to make it a little more specific. Example can be connection of external device such as proximity sensor. Sensor outputs can be different depending on a sensor itself and also on a particular application. Following pictures display some examples of sensor outputs and their connection with a PLC controller. Sensor output actually marks the size of a signal given by a sensor at its output when this sensor is active. In one case this is +V (supply voltage, usually 12 or 24V) and in other case a GND (0V). Another thing worth mentioning is that sinking-sourcing and sourcing - sinking pairing is always used, and not sourcing-sourcing or sinking-sinking pairing.

If we were to make type of connection more specific, we'd get combinations as in following pictures (for more specific connection schemas we need to know the exact sensor model and a PLC controller model).

Output lines

PLC controller output lines usually can be:

-transistors in PNP connection

-transistors in NPN connection

-relays

The following two pictures display a realistic way how a PLC manages external devices. It ought to be noted that a main difference between these two pictures is a position of "output load device". By "output load device" we mean some relay, signalization light or similar.

How something is connected with a PLC output depends on the element being connected. In short, it depends on whether this element of output load device is activated by a positive supply pole or a negative supply pole.

author: Nebojsa Matic