There are some methods to do PLC programming. The programming methods can be with Logic Ladder Diagram, mneumonic (statement list), and / or function block diagram.

One of the PLC programming methods that are very commonly used programming using PLC ladder diagram. The method is practical and easy to understand. The programmer in charge of writing a program should describe an electronic switch circuit. It can be designed to perform the conversion of electronic circuits that already exist, then replace the switch function according to the functions available to software programmers.

A ladder diagram consists of a downward line on the left side with lines branching to the right. Existing line on the left side is called the bus bar, whereas the branching lines are lines of instructions or steps. Instructions are placed along the line of a variety of conditions linked to the other instructions on the right side. Logic combination of the conditions stated when and how the existing instructions on the right side is done.

As shown in Figure 1 is, along the lines of instructions can branch out again and then joined again. The lines of vertical pairs (such as capacitors symbol) is called the condition. The pair of vertical lines no diagonal line called the Normal Open - Normally Open or NO and related instruction LOAD (LD), AND or OR. While the couple have a vertical line was a diagonal line called the Normal Closed - Normally Close or NC, and related instructions LD NOT, AND NOT or OR NOT.

PLC is still used mostly as a strand of logic, as generally in strings of logic / digital solutions to these problems will be easier if each input and output components are presented in digital logic, involving the truth table, set the output equation in the table are based on binary numbers, then simplify the equation by using Karnaugh Map.

Here are some examples of conversion from basic logic gates in the Ladder Diagram. (Example given has 2 inputs and 1 output).

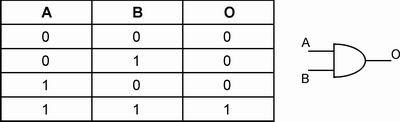

Logic AND

The truth table of logic AND is as follows,

Conversion to Ladder Diagram,

Conversion to Ladder Diagram,

Logic OR

The truth table of logic OR is as follows,

Conversion to Ladder Diagram,

Conversion to Ladder Diagram,

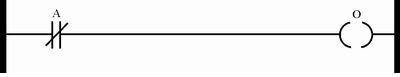

Logic NOT

The truth table of logic NOT is as follows,

Conversion to Ladder Diagram,

Conversion to Ladder Diagram,

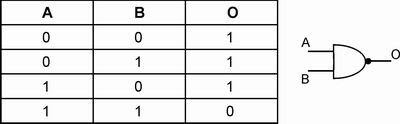

Logic NAND

Logic NAND is a development of logic AND, OR and NOT. The truth table is as follows,

The truth table above have the following equation,

The truth table above have the following equation, O = (A.B) '= A' + B '

So the conversion to Ladder Diagram,

Logic NOR

This logic is also the development of the logic AND, OR and NOT. The truth table is as follows,

The truth table above have the following equation,

The truth table above have the following equation, O = (A + B) '= A'. B '

So the conversion to Ladder Diagram,

Logic XOR

Similarly, the logic of the previous ones. This logic is also the development of AND, OR and NOT. This logic is widely used in summing strand (adder). The truth table is as follows,

The truth table above have the following equation,

The truth table above have the following equation, O = A o B = A '. B + A. B'

So the conversion to Ladder Diagram,

Labels:

PLC Articles

PLC Articles