Standard Sequence Programming for PLC Programming is the original made in program-plc.blogspot.com and FREE for You

Standard Sequence for PLC Programming consists of :

1. Input Condition

2. Trigger And Sensor Condition

3. Output Condition, And

4. Controller

The following is a diagram of the Input, Trigger, Output and Controller

The following example the use of Standard Sequence Programming (Input, Trigger, Output and Controller) in ladder diagram :

The following example the use of Standard Sequence Programming (Input, Trigger, Output and Controller) in ladder diagram :

1. Example Input Condition

1. Example Input Condition

Legend:

Legend:

I-1 : Input Condition 1

I-2 : Input Condition 2

I-3 : Input Condition 3

O-4 : Output Condition 4

S-3 : Sensor 3

C-1 : Output Controller 1

PLC Input : PLC Input from PLC Hardware

2. Example Trigger And Sensor Condition

Legend:

Legend:

Tr : Trigger to Controller

C-1 : Output Controller 1

C-2 : Output Controller 2

C-3 : Output Controller 3

C-4 : Output Controller 4

S-1 : Sensor 1

S-2 : Sensor 2

S-3 : Sensor 3

S-4 : Sensor 4

I-2 : Input Condition 2

I-3 : Input Condition 3

STEP0 : Waiting Start = ON, Waiting All Origin = ON, etc.

STEP1 : Sequence 1

STEP2 : Sequence 2

STEP3 : Sequence 3

3. Example Output Condition

Legend:

Legend:

O-1 : Output Condition 1

O-2 : Output Condition 2

O-3 : Output Condition 3

O-4 : Output Condition 4

C-2 : Output Controller 2

C-3 : Output Controller 3

C-4 : Output Controller 4

S-3 : Sensor 3

S-4 : Sensor 4

I-1 : Input Condition 1

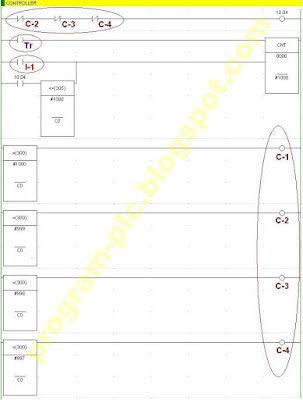

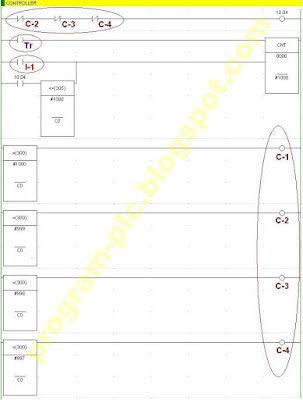

4. Example Controller

Legend:

Tr : Trigger from "2. Trigger And Sensor Condition"

C-1 : Output Controller 1

C-2 : Output Controller 2

C-3 : Output Controller 3

C-4 : Output Controller 4

I-1 : Input Condition 1

4.1. Controller for Siemens PLC

4.2. Controller for Allen Bradley PLC

4.2. Controller for Allen Bradley PLC

4.3. Controller for Omron PLC

4.3. Controller for Omron PLC

4.4. Controller for Mitsubishi PLC

4.4. Controller for Mitsubishi PLC

4.5. Controller for Keyence PLC

4.5. Controller for Keyence PLC

4.6. Controller for GE Fanuc PLC

4.6. Controller for GE Fanuc PLC

Application for Standard Sequence Programming :

1. Simple Movement/Process :

--> PLC Control for 3 Movement

2. Complex Movement/Process :

--> PLC Control for Automatic Welding Machine

Standard Sequence for PLC Programming consists of :

1. Input Condition

2. Trigger And Sensor Condition

3. Output Condition, And

4. Controller

The following is a diagram of the Input, Trigger, Output and Controller

The following example the use of Standard Sequence Programming (Input, Trigger, Output and Controller) in ladder diagram :

The following example the use of Standard Sequence Programming (Input, Trigger, Output and Controller) in ladder diagram :  1. Example Input Condition

1. Example Input Condition  Legend:

Legend:I-1 : Input Condition 1

I-2 : Input Condition 2

I-3 : Input Condition 3

O-4 : Output Condition 4

S-3 : Sensor 3

C-1 : Output Controller 1

PLC Input : PLC Input from PLC Hardware

2. Example Trigger And Sensor Condition

Legend:

Legend:Tr : Trigger to Controller

C-1 : Output Controller 1

C-2 : Output Controller 2

C-3 : Output Controller 3

C-4 : Output Controller 4

S-1 : Sensor 1

S-2 : Sensor 2

S-3 : Sensor 3

S-4 : Sensor 4

I-2 : Input Condition 2

I-3 : Input Condition 3

STEP0 : Waiting Start = ON, Waiting All Origin = ON, etc.

STEP1 : Sequence 1

STEP2 : Sequence 2

STEP3 : Sequence 3

3. Example Output Condition

Legend:

Legend:O-1 : Output Condition 1

O-2 : Output Condition 2

O-3 : Output Condition 3

O-4 : Output Condition 4

C-2 : Output Controller 2

C-3 : Output Controller 3

C-4 : Output Controller 4

S-3 : Sensor 3

S-4 : Sensor 4

I-1 : Input Condition 1

4. Example Controller

Legend:

Tr : Trigger from "2. Trigger And Sensor Condition"

C-1 : Output Controller 1

C-2 : Output Controller 2

C-3 : Output Controller 3

C-4 : Output Controller 4

I-1 : Input Condition 1

4.1. Controller for Siemens PLC

4.2. Controller for Allen Bradley PLC

4.2. Controller for Allen Bradley PLC 4.3. Controller for Omron PLC

4.3. Controller for Omron PLC 4.4. Controller for Mitsubishi PLC

4.4. Controller for Mitsubishi PLC 4.5. Controller for Keyence PLC

4.5. Controller for Keyence PLC 4.6. Controller for GE Fanuc PLC

4.6. Controller for GE Fanuc PLCApplication for Standard Sequence Programming :

1. Simple Movement/Process :

--> PLC Control for 3 Movement

2. Complex Movement/Process :

--> PLC Control for Automatic Welding Machine