Motion control / positioning control of three axes using Arduino CNC/ GRBL.

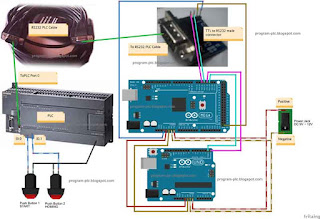

This application using two arduino, one arduino UNO for CNC controller/GRBL and one arduino ATMega for GCode Sender and connect to PLC.

Communication for GCode Sender between Arduino UNO and Arduino ATMega using Serial (TTL serial port).

Communication between PLC and Arduino ATMega using Modbus Protocol.

Three axis consisting of the X axis, Y axis and Z axis is set in the PLC Modbus Registers.

For simulation, I use stepper motor from DVD-ROM Drive.

Servo Motor/Stepper Motor connect to Arduino CNC and PLC

Hardware:

1. Stepper Motor / Servo Motor:

I use stepper motor from DVD-ROM Drive.

I use small motor, for big motor, I don't have money : Donate

2. Driver/Servo Amplifier with support voltage 5 Volt for STEP PULSE and DIRECTION:

I use A4988 Micro Stepping Motor Driver.

3. Arduino UNO

4. Arduino ATMega

5. TTL to RS232 male connector

6. RS232 PLC Cable

7. Siemens PLC or other PLCs that support Modbus

8. Power Supply 12 Volt

9. Micro Limit Switch for Homing Stepper Motor Drive.

10. Push Button for Start: connect to I0.0 on PLC Input

11. Push Button for Homing: connect to I0.1 on PLC Input

Hardware Setting and Connection:

1. Arduino CNC layout: https://github.com/grbl/grbl/wiki/Connecting-Grbl

2. The specification of the DVD-ROM Drive:

2a.The maximum current of roughly 200mA

2b. Stepper motor have 20 steps per revolution.

2c. The lead screw has a pitch of 3mm per revolution.

2d. In Driver, I use Micro step Resolution = 16

2d. STEPS PER MM = (20 X 16) STEPS PER 3 MM = 106.667 (Parameter Setting in Grbl)

Download Project File:

1. Download Arduino libraries, click here

Copy-Paste folder: SimpleModbusMaster and Grbl9fUno into folder C:\Program Files (x86)\Arduino\libraries

2. Upload program to Arduino UNO:

In Arduino Software (IDE): Click File -- Click Examples -- Click Grbl9fUno -- Click GRBL9funo And Then Click Upload Icon

3. Upload program to Arduino ATMega:

In Arduino Software (IDE): Click File -- Click Examples -- Click SimpleModbusMaster -- Click MotionControlForPLC And Then Click Upload Icon

4. Download PLC Ladder Programming, click here

5. Download Hardware Connection, click here

6. Download A4988 Micro Stepping Motor Driver, click here

Arduino ATMega Code:

This application using two arduino, one arduino UNO for CNC controller/GRBL and one arduino ATMega for GCode Sender and connect to PLC.

Communication for GCode Sender between Arduino UNO and Arduino ATMega using Serial (TTL serial port).

Communication between PLC and Arduino ATMega using Modbus Protocol.

Three axis consisting of the X axis, Y axis and Z axis is set in the PLC Modbus Registers.

For simulation, I use stepper motor from DVD-ROM Drive.

Servo Motor/Stepper Motor connect to Arduino CNC and PLC

Hardware:

1. Stepper Motor / Servo Motor:

I use stepper motor from DVD-ROM Drive.

I use small motor, for big motor, I don't have money : Donate

2. Driver/Servo Amplifier with support voltage 5 Volt for STEP PULSE and DIRECTION:

I use A4988 Micro Stepping Motor Driver.

3. Arduino UNO

4. Arduino ATMega

5. TTL to RS232 male connector

6. RS232 PLC Cable

7. Siemens PLC or other PLCs that support Modbus

8. Power Supply 12 Volt

9. Micro Limit Switch for Homing Stepper Motor Drive.

10. Push Button for Start: connect to I0.0 on PLC Input

11. Push Button for Homing: connect to I0.1 on PLC Input

Hardware Setting and Connection:

1. Arduino CNC layout: https://github.com/grbl/grbl/wiki/Connecting-Grbl

2. The specification of the DVD-ROM Drive:

2a.The maximum current of roughly 200mA

2b. Stepper motor have 20 steps per revolution.

2c. The lead screw has a pitch of 3mm per revolution.

2d. In Driver, I use Micro step Resolution = 16

2d. STEPS PER MM = (20 X 16) STEPS PER 3 MM = 106.667 (Parameter Setting in Grbl)

Download Project File:

1. Download Arduino libraries, click here

Copy-Paste folder: SimpleModbusMaster and Grbl9fUno into folder C:\Program Files (x86)\Arduino\libraries

2. Upload program to Arduino UNO:

In Arduino Software (IDE): Click File -- Click Examples -- Click Grbl9fUno -- Click GRBL9funo And Then Click Upload Icon

3. Upload program to Arduino ATMega:

In Arduino Software (IDE): Click File -- Click Examples -- Click SimpleModbusMaster -- Click MotionControlForPLC And Then Click Upload Icon

4. Download PLC Ladder Programming, click here

5. Download Hardware Connection, click here

6. Download A4988 Micro Stepping Motor Driver, click here

Arduino ATMega Code:

#include <SimpleModbusMaster.h> //Arduino Serial Port Connect to Port 0 of Siemens PLC S7 200 //for more info program-plc.blogspot.com #define slaveAddr 1 #define baud 9600 #define timeout 1000 #define polling 200 #define retry_count 0 #define TxEnablePin 2 enum { PACKET1, PACKET2, TOTAL_NO_OF_PACKETS }; Packet packets[TOTAL_NO_OF_PACKETS]; packetPointer packet1 = &packets[PACKET1]; packetPointer packet2 = &packets[PACKET2]; unsigned int readRegs[1]; unsigned int writeRegs[7]; unsigned int Motion_Command = 0; bool CommandEx=true; int stat=0; long MPosX=0; long WPosX=0; void setup() { Serial.begin(9600); Serial1.begin(115200); ResetGrbl(); modbus_construct(packet1, slaveAddr, READ_HOLDING_REGISTERS, 7, 1, readRegs); modbus_construct(packet2, slaveAddr, PRESET_MULTIPLE_REGISTERS, 0, 7, writeRegs); modbus_configure(&Serial2, baud, SERIAL_8E1, timeout, polling, retry_count, TxEnablePin, packets, TOTAL_NO_OF_PACKETS); } void loop() { modbus_update(); unsigned int p2sr=packet2->successful_requests; Serial.println(p2sr); Motion_Command = (word)readRegs[0]; CurrentStatus(); Long2unInt(MPosX,&writeRegs[0],&writeRegs[1]); Long2unInt(WPosX,&writeRegs[2],&writeRegs[3]); writeRegs[4] = stat; writeRegs[5]= (word)random(1, 32760);; if(CommandEx){ CommandEx=false; switch(Motion_Command) { case 1: //Reset Grbl ResetGrbl(); break; case 2: //Kill Alarm Lock Sender("$X", "ok",5000);//Kill Alarm Lock break; case 3: //Run Homing Cycle while(packet2->successful_requests==p2sr){ stat = 5;//Home=5 writeRegs[4] = stat; modbus_update(); }; Sender("$H", "ok",60000);// Run Homing Cycle break; case 4: //cycle start Sender("~", "ok",5000);//cycle start break; case 5: //feed hold Sender("!", "ok",5000);//feed hold break; case 6://go to x0 Sender("g90 g0 x0", "ok",5000); break; case 7://increment 10.5mm for pills with 10.5mm diameter Sender("g91 g1 x-10.5 f400", "ok",5000); break; case 8://GCode Programming for Cutting Material Sender("g90 g0 x-25", "ok",5000);// High Speed with G0 Sender("g90 g1 x-33 f60", "ok",5000);//Low Speed / Cutting Process with G1 Sender("g90 g1 x-25 f60", "ok",5000);//Low Speed / Cutting Process with G1 Sender("g90 g0 x0", "ok",5000);// High Speed with G0 break; default: break; } writeRegs[6]= (word)Motion_Command; } if(Motion_Command==0){ CommandEx=true; writeRegs[6]= (word)0; } } String Sender(String command, char *UntilChar,int millisWait) { Serial1.println(command); //Serial.println(command); String data=""; unsigned long start; start = millis(); while (millis()-start<millisWait) { while(Serial1.available()>0) { char c =Serial1.read(); data=data+c; } if (data.indexOf(UntilChar)!=-1)break; if (data.indexOf("Reset to continue")!=-1){ ResetGrbl(); break; } } //Serial.println(data); return data; } void ResetGrbl() { Serial1.write(0x18); //Reset Serial.println("ResetGrbl"); String data=""; unsigned long start; start = millis(); while (millis()-start<5000) { while(Serial1.available()>0) { char c =Serial1.read(); data=data+c; } if (data.indexOf("['$' for help]")!=-1)return; } asm volatile (" jmp 0"); while(1); } void CurrentStatus(){ String cur = Sender("?", "ok",5000); stat=255;//default if (cur==""){ stat=11; //No Data=11 ResetGrbl(); }else{ if (cur.indexOf("Idle")!=-1)stat=1;//Idle=1 if (cur.indexOf("Queue")!=-1)stat=2;//Queue=2 if (cur.indexOf("Run")!=-1)stat=3;//Run=3 if (cur.indexOf("Hold")!=-1)stat=4;//Hold=4 if (cur.indexOf("Home")!=-1)stat=5;//Home=5 if (cur.indexOf("Check")!=-1)stat=6;//Check=6 if (cur.indexOf("Alarm")!=-1)stat=7;//Alarm=7 if (cur.indexOf("ALARM: Hard/soft limit")!=-1)stat=8;//ALARM=8 if (cur.indexOf("Reset to continue")!=-1)stat=9;//Reset to continue=9 if (cur.indexOf("'$H'|'$X' to unlock")!=-1)stat=9;//Reset to continue=10 if((cur.indexOf("<")!=-1) && (cur.indexOf(">")!=-1)){ if((cur.indexOf(",MPos:")!=-1) && (cur.indexOf(",WPos:")!=-1)){ String buff = cur.substring(cur.indexOf(",MPos:")+6,cur.indexOf(",WPos:")); String buffvalX = buff.substring(0,buff.indexOf(",")); buffvalX.replace(".",""); MPosX= (long)buffvalX.toInt(); buff = cur.substring(cur.indexOf(",WPos:")+6,cur.indexOf(">")); buffvalX = buff.substring(0,buff.indexOf(",")); buffvalX.replace(".",""); WPosX = (long)buffvalX.toInt(); } } } } void Long2unInt(long l,unsigned int *i0,unsigned int *i1) { *i0 = (l & 0xFFFF); unsigned int buff = l >> 16; *i1 = (buff & 0xFFFF); }

Labels:

Motion Control

PLC and Arduino

PLC and CNC

PLC and Servo

PLC Application

Positioning Control

Motion Control

PLC and Arduino

PLC and CNC

PLC and Servo

PLC Application

Positioning Control