As the impact of Servo Pneumatic global industrial process which is remarkably known has developed over decades, there are also so many of device which had develeped also. Each of the product types which need by the industrieas are the product that can operated by lastest technology.

One of the lastest Servo Pneumatic technologies which has developed and operating by industries are the automation solution systems. That was kind of technology which can handled the aspect on controlling and monitoring automaticly by using integrated device which operated via PLC’s or IPC’s as the HMI or Human Machine Interface.

Those Servo Pneumatic systems are complex and involved several device working simultaneously. Than thts why it was fully reasonable for the enggineers are always looking a brand new device which suported with this systems. Kind of device are depend on the types of industries, for example automatif welded system in automotive industries, or automatif sawing systems at the timber industries.

One of the important device are servo pneumatic, it was kind of the device which is need to operated any moving parts in kind of the device we’ve been talked before. To get closser about the product lets found the information through this articles.

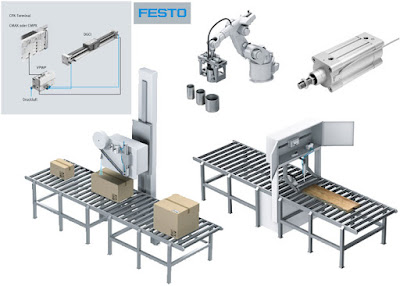

Types and Features For Each Of FESTO Servo Pneumatics

There are many types of FESTO servo pneumatics models or types. Each has been tailored for increasing productivity and or better and ideal industrial automation solution systems and process. Here are some of the product included with the information for product features and specification.• Servo Pneumatic CPX-CMAX-C1-1

Prepared as positioning module servo pneumatics, this device are well prepared with best technical specification aspect such as : 1 until 450kg horizontal and 1 until 150kg vertical moving loads, 30 until 4200N at 6 bar controlled force, ≥ ±0.2 mm positioning accuracy, Max. 3 m/s travel speed, and Max. 30 m/s2 acceleration aspect.• Servo Pneumatic CPX-CMPX-C-1-H1

This moel are design and tailored to be functioning as soft stop electronic end-position controller. It was well prepared and ready to use device for working with highly dynamic movement of loads up to 450 kg. There are several technical aspect which make it possible such as : all fieldbuses available and FEC and CEC-C1 actuation front end controller.• Servo Pneumatic VPWP Directional Proportional Control Valve

For the time being gaining the maximum servopneumatic productivity are impossible without teamworking with the VPWP directional proportional control valve. The main function of this device are gives better diagnostic and monitoring edge while operating with the servo pneumatics such as, CPX-CMAX or CPX-CPMX Soft Stop.• Servo Pneumatic VABP Double-Sub Base

This parts are other supported following servo pneumatics device which can belonging for Performance Level C single-channel switch-off functions. There are lots of benefits which can users grant by using this parts such as; s1-s1' stopping systems, s2-s2' de-energise, s4-s4' switch off power and reverse at reduced speed with s3-s2' or s2-s3' switch off systems.There are so many of servo pneumatics or servo standard developers. But FERSO are one of greater named which prepared so many types which can used depend on what users needed and intention.