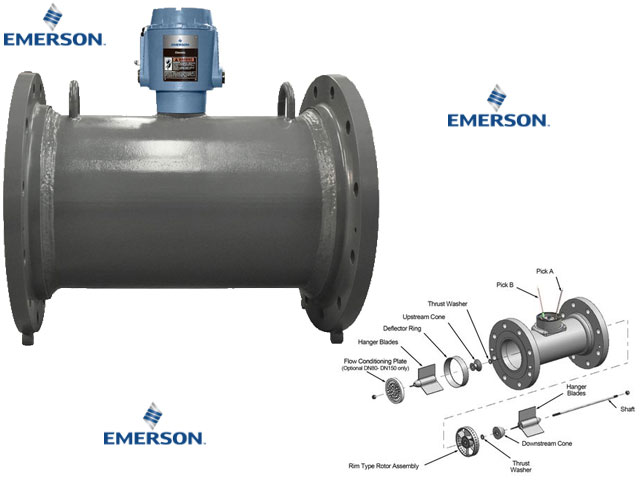

Emerson Turbine Flow Meters for Liquid has simple Working Principle and designed to maximize throughout and minimize pressure drop by delivering high-frequency pulse resolution to account for minute increments of the flow rate. Minimize fiscal measurement uncertainty is one of this flow meters capability. Other, it also offer reliable, measurement with minimal flow meter maintenance required and simple to operate and maintain.

Image by https://www.emerson.com

Emerson Turbine Flow Meters for Liquid has reliable, cost-effective method for achieving accurate flow measurement by impinges upon turbine blades. This is free working process to rotate about an axis and maintain high flow rates along the center line of the turbine housing over a wide range of flow rates, temperatures, compositions and viscosities.

Emerson Turbine Flow Meters for Liquid is linear to the flow rate and taken by an electrical pickoff(s) mounted on the flow meter body rimmed rotor (6-in) and larger line size meters. This body rimmed rotor blades to the stream governs the angular velocity and the output frequency of the meter as major advantage of the turbine flow meter.

Emerson Turbine flow meters for liquids used for volumetric total flow and/or flow rate measurement and designed to ensure linearity and repeatability, making the turbine meter an ideal device. Emerson Turbine flow meters serve a variety of hydrocarbon applications, impinging upon the blade causes the rotor to spin including fiscal and custody transfer, check metering or blending/batching.

Emerson Turbine Flow Meters for Liquid has reliable, cost-effective method for achieving accurate flow measurement by impinges upon turbine blades. This is free working process to rotate about an axis and maintain high flow rates along the center line of the turbine housing over a wide range of flow rates, temperatures, compositions and viscosities.

Emerson Turbine Flow Meters for Liquid equipped with angular (rotational) velocity of the turbine rotor with a maximum error

Emerson Turbine Flow Meters for Liquid with angular (rotational) velocity of the turbine rotor can be totalized with a maximum error. This is one pulse regardless of the volume measured with directly proportional to the fluid velocity flowing through the turbine in alignment with the fluid flow. By resulting output it is over an extended flow range and offer pulse output.Emerson Turbine Flow Meters for Liquid is linear to the flow rate and taken by an electrical pickoff(s) mounted on the flow meter body rimmed rotor (6-in) and larger line size meters. This body rimmed rotor blades to the stream governs the angular velocity and the output frequency of the meter as major advantage of the turbine flow meter.

Emerson Turbine Flow Meters for Liquid expanding blade hanger for assembly holds the turbine rotor

Emerson Turbine flow meters for liquids are cost-effective and in service worldwide expanding blade hanger for assembly holds the turbine rotor. This is as proportional to the flow rate improves pulse resolution, particularly in DN150 as refined product loading and offloading. Emerson Turbine flow meters has quickly size a turbine meter for fiscal flow measurement to your application with our easy-to-use tool.Emerson Turbine flow meters for liquids used for volumetric total flow and/or flow rate measurement and designed to ensure linearity and repeatability, making the turbine meter an ideal device. Emerson Turbine flow meters serve a variety of hydrocarbon applications, impinging upon the blade causes the rotor to spin including fiscal and custody transfer, check metering or blending/batching.