Video about the results of the PLC and Computer

(Laptop) communication

Architecture of PLC and Computer Communication:

Architecture of PLC and Computer Communication:

Remarks of PLC and Computer Communication Architecture:

PLC:

1. Siemens S7-200 PLC with PPI Communication Port

PLC Cable:

2. PLC Cable: USB to PPI (RS485)

Adapter for Siemens S7-200

Computer:

3. Computer or Laptop

4. Windows 7 Operating System, I use Windows 7 64Bit

5. PLC Cable Driver for Windows 7

6. Visual Basic 2010 Express

A. Prepared of Hardware and software for PLC and

Computer Communication

1. Siemens S7-200, CPU 226 CN

2. USB to PPI Adapter for Siemens S7-200

3. Download PLC Cable driver for windows 7, Click: CP210x_VCP_Win_XP_S2K3_Vista_7

4. Installation Siemens S7-200 PLC, PLC Cable and

Laptop

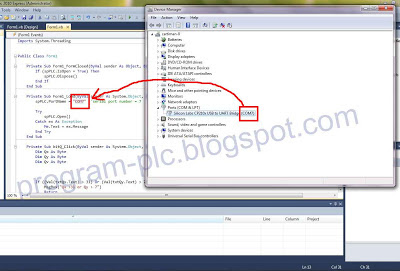

5. How to Serial Port Number Check in Windows 7

Video About How to Serial Port Number Check

B. Visual Basic Express Programming for PLC and

Computer Communication

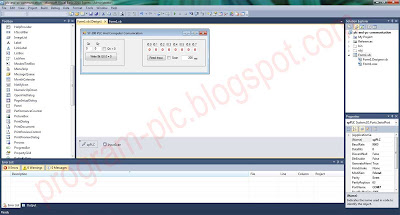

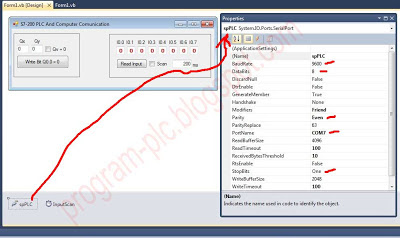

1. Layout Form in Visual Basic

2. Communication setting in SerialPort Properties

3. Visual Basic Code

Imports System.Threading

Public Class Form1

Private Sub

Form1_FormClosed(ByVal sender As Object, ByVal e As

System.Windows.Forms.FormClosedEventArgs) Handles Me.FormClosed

If (spPLC.IsOpen = True)

Then

spPLC.Dispose()

End If

End Sub

Private Sub

Form1_Load(ByVal sender As System.Object, ByVal e As System.EventArgs) Handles

MyBase.Load

spPLC.PortName = "COM7" 'serial port number

= 7

Try

spPLC.Open()

Catch ex As Exception

Me.Text = ex.Message

End Try

End Sub

Private Sub

bitQ_Click(ByVal sender As System.Object, ByVal e As System.EventArgs) Handles

bitQ.Click

Dim Qx As Byte

Dim Qy As Byte

Dim Qv As Byte

If ((Val(txtQx.Text) > 31) Or (Val(txtQy.Text) > 7)) Then

MsgBox("Qx >31 or Qy > 7")

Return

End If

Qx = CByte(Val(txtQx.Text)) '

Qx.y

Qy = CByte(Val(txtQy.Text)) '

Qx.y

If (ckQv.Checked = True)

Then

Qv = 1 ' Q Value

Else

Qv = 0 ' Q Value

End If

Dim str_write(0 To

37) As Byte

Dim Temp_FCS As VariantType

Dim i As Long

bitQ.Enabled = False

str_write(0) = &H68

str_write(1) = &H20

str_write(2) = &H20

str_write(3) = &H68

str_write(4) = &H2

str_write(5) = &H0

str_write(6) = &H7C

str_write(7) = &H32

str_write(8) = &H1

str_write(9) = &H0

str_write(10) = &H0

str_write(11) = &H43

str_write(12) = &H1

str_write(13) = &H0

str_write(14) = &HE

str_write(15) = &H0

str_write(16) = &H5

str_write(17)

= &H5

str_write(18) = &H1

str_write(19) = &H12

str_write(20) = &HA

str_write(21) = &H10

str_write(22) = &H1 'len = 1

str_write(23) = &H0

str_write(24) = &H1

str_write(25) = &H0

str_write(26) = &H0 ' type q

str_write(27) = &H82 'type q

str_write(28) = &H0

str_write(29) = &H0

str_write(30) = Qx * 8 + Qy

str_write(31) = &H0

str_write(32) = &H3

str_write(33) = &H0

str_write(34) = &H1

str_write(35) = Qv

For i = 4 To 35

Temp_FCS = Temp_FCS + str_write(i)

Next

str_write(36) = Temp_FCS Mod 256

str_write(37) = &H16

If (spPLC.IsOpen = True)

Then

' Send the binary

data out the port

spPLC.Write(str_write, 0, str_write.Length)

Thread.Sleep(100) 'wait

100ms

End_comm() 'end Communication

End If

bitQ.Enabled = True

End Sub

Private Sub

End_comm()

'End Communication

Dim str_val(0 To 5) As Byte

spPLC.ReadExisting()

str_val(0) = &H10

str_val(1) = &H2

str_val(2) = &H0

str_val(3) = &H5C

str_val(4) = &H5E

str_val(5) = &H16

If (spPLC.IsOpen = True)

Then

spPLC.Write(str_val, 0, str_val.Length)

End If

End Sub

Private Sub

ckQv_CheckedChanged(ByVal sender As System.Object, ByVal e As System.EventArgs) Handles

ckQv.CheckedChanged

If (ckQv.Checked = True)

Then

ckQv.Text = "Qv = 1"

bitQ.Text = "Write Bit Q" +

txtQx.Text + "." + txtQy.Text + " = 1"

Else

ckQv.Text = "Qv = 0"

bitQ.Text = "Write Bit Q" +

txtQx.Text + "." + txtQy.Text + " = 0"

End If

End Sub

Private Sub

txtQx_TextChanged(ByVal sender As System.Object, ByVal e As System.EventArgs) Handles

txtQx.TextChanged

If (ckQv.Checked = True)

Then

ckQv.Text = "Qv = 1"

bitQ.Text = "Write Bit Q" +

txtQx.Text + "." + txtQy.Text + " = 1"

Else

ckQv.Text = "Qv = 0"

bitQ.Text = "Write Bit Q" +

txtQx.Text + "." + txtQy.Text + " = 0"

End If

End Sub

Private Sub

txtQy_TextChanged(ByVal sender As System.Object, ByVal e As System.EventArgs) Handles

txtQy.TextChanged

If (ckQv.Checked = True)

Then

ckQv.Text = "Qv = 1"

bitQ.Text = "Write Bit Q" +

txtQx.Text + "." + txtQy.Text + " = 1"

Else

ckQv.Text = "Qv = 0"

bitQ.Text = "Write Bit Q" +

txtQx.Text + "." + txtQy.Text + " = 0"

End If

End Sub

Private Sub

Ixy_Click(ByVal sender As

System.Object, ByVal

e As System.EventArgs)

Handles Ixy.Click

Dim str_read(0 To 32)

As Byte

Dim i As Integer

Dim Temp_FCS As VariantType

Dim Rx As String

Rx =

0 ' Read from I0.0

str_read(0) = &H68

str_read(1) = &H1B

str_read(2) = &H1B

str_read(3) = &H68

str_read(4) = &H2

str_read(5) = &H0

str_read(6) = &H6C

str_read(7) = &H32

str_read(8) = &H1

str_read(9) = &H0

str_read(10) = &H0

str_read(11) = &H0

str_read(12) = &H0

str_read(13) = &H0

str_read(14) = &HE

str_read(15) = &H0

str_read(16) = &H0

str_read(17) = &H4

str_read(18) = &H1

str_read(19) = &H12

str_read(20) = &HA

str_read(21) = &H10

str_read(22) = &H8 'read len 1=bit, 8=byte

str_read(23) = &H0

str_read(24) = &H1

str_read(25) = &H0

str_read(26) = &H0 ' type Ixy

str_read(27) = &H81 'type

Ixy=&H81, Qxy=&H82

str_read(28) = &H0

str_read(29) = (Str(Rx) * 8) \ 256

str_read(30) = (Str(Rx) * 8) Mod 256

For i = 4 To 30

Temp_FCS = Temp_FCS + str_read(i)

Next i

str_read(31) = Temp_FCS Mod 256

str_read(32) = &H16

If (spPLC.IsOpen = True)

Then

' Send the binary data out the port

spPLC.Write(str_read, 0, str_read.Length)

Thread.Sleep(100) 'wait

100ms

End_comm() 'end communication

End If

End Sub

Private DisplayDelegate As

New DisplayData(AddressOf Display)

Private Sub

spPLC_DataReceived(ByVal sender As System.Object, ByVal e As

System.IO.Ports.SerialDataReceivedEventArgs)

Handles spPLC.DataReceived

'Suppose that you want to use the built-in SerialPort

control (System.IO.Ports.SerialPort)

'this code is equivalent to the EnhancedSerialPort

DataReceived code

Dim BytesAvailable As

Integer = spPLC.BytesToRead

If BytesAvailable >= 29 Then

'Total byte data from I = 29

Dim

Buffer(0 To BytesAvailable - 1) As Byte

spPLC.Read(Buffer, 0, BytesAvailable)

Me.BeginInvoke(DisplayDelegate, Buffer)

End If

End Sub

Public Delegate Sub DisplayData(ByVal Buffer() As Byte)

'This delegate routine marshals receive data from the

receive thread context DataReceived to the Windows Form STAThread context

Private Sub Display(ByVal Buffer() As Byte)

Dim xyval As Byte

xyval

= Buffer(25)

txtI00.Text = (xyval And 1) / 1

txtI01.Text = (xyval And 2) / 2

txtI02.Text = (xyval And 4) / 4

txtI03.Text = (xyval And 8) / 8

txtI04.Text = (xyval And 16) / 16

txtI05.Text = (xyval And 32) / 32

txtI06.Text = (xyval And 64) / 64

txtI07.Text = (xyval And 128) / 128

End Sub

Private Sub

InputScan_Tick(ByVal sender As System.Object, ByVal e As System.EventArgs) Handles

InputScan.Tick

Ixy_Click(New Object(),

New EventArgs())

End Sub

Private Sub

scan_CheckedChanged(ByVal sender As System.Object, ByVal e As System.EventArgs) Handles

scan.CheckedChanged

If (Val(TimeScan.Text) < 200) Then TimeScan.Text = 200

InputScan.Interval = Val(TimeScan.Text)

If (scan.Checked = True)

Then

InputScan.Enabled = True

Ixy.Enabled = False

Else

InputScan.Enabled = False

Ixy.Enabled = True

End If

End Sub

End Class

4. Download Visual basic Code

3. Project File

Video about How to use Download File: PLC and Computer

Communication