PLC Type FX-Mitsubishi , Name Input / Output PLC :

INPUT PLC :

X000 ; Push Button Start

X001 ; Push Button Stop

X002 ; Selector Switch 1

X003 ; Selector Switch 2

X004 ; Selector Switch 3

X005 ; Selector Switch 4

X006 ; Sensor Bottle 1

X007 ; Sensor Bottle 2

X010 ; Sensor Bottle 3

X011 ; Sensor Bottle 4

X012 ; Digital Flow Switch 1

X013 ; Digital Flow Switch 2

X014 ; Digital Flow Switch 3

X015 ; Digital Flow Switch 4

X016 ; Proximity for Count Revolution

X017 ; Fluid Sensor

X020 ; Motor Feedback Alarm for Screw Conveyor

X021 ; Limit Switch (LS) Nozzle Down

X022 ; Limit Switch (LS) Nozzle Up

OUTPUT PLC :

Y000 ; Motor ( Motor Running ) for Screw Conveyor

Y001 ; Solenoid for Cylinder Nozzle Up

Y002 ; Solenoid for Cylinder Nozzle Down

Y003 ; Single Solenoid for Drain Nozzle 1

Y004 ; Single Solenoid for Drain Nozzle 2

Y005 ; Single Solenoid for Drain Nozzle 3

Y006 ; Single Solenoid for Drain Nozzle 4

Y007 ; Single Solenoid for Filling Nozzle 1

Y010 ; Single Solenoid for Filling Nozzle 2

Y011 ; Single Solenoid for Filling Nozzle 3

Y012 ; Single Solenoid for Filling Nozzle 4

Y013 ; Single Solenoid for Pneumatic Pump 1

Y014 ; Single Solenoid for Pneumatic Pump 1

Y015 ; Single Solenoid for Pneumatic Pump 1

Y016 ; Single Solenoid for Pneumatic Pump 1

Please Download Picture Programming Ladder PLC :

PLC Mitsubishi Programming for Filling Machine

Reading Ladder PLC Programming for Filling Machine :

Step 1 :

a.If X000 = ON And X001 = OFF And X017 = ON And X020 = ON Then M32 = ON And M33 = Momentary ON ( Pulse ).

b.M33 For Return To Origin Signal

c.If M32 = ON Then ALL System Ready ( Master Control M100 = ON ).

Step 2 :

For Pump ON and Drain Process for 1 Nozzle, Example Nozzle 1

a. If X002 = ON And M48 = OFF Then M0 = ON.

b. If Y013 = ON And Y007 = OFF Then M4 = ON.

c. If Y013 = ON And Y003 = ON And X012 = OFF Then T0 Activated ( Can be Setting for Stability ).

d. If T0 = ON Then SET M48 = Hold ON.

e. If X002 = OFF Then RST M48 = OFF.

See Picture for Setting Stability Flow Switch OFF :

Step 3 :

Filling Process

a. If (Y013 = ON And X006 = ON) Or (Y014 = ON And X007= ON) Or (Y015 = ON And X010= ON) Or (Y016= ON And X011= ON) Then M8 = ON.

b. If M8 = ON And X022 = ON And Y000 = OFF And M25 = OFF Then M9 = ON (Latching ON) And M10 = Momentary ON ( Pulse).

c. If M10 = ON And M22 = OFF And M9 = ON Then M11 = ON (Latching ON).

d. If M11 = ON And X021 = ON And M22 = OFF And M9 = ON Then M12 = ON (Latching ON).

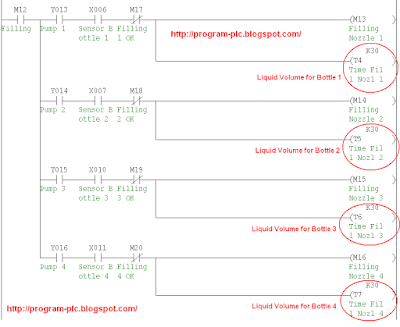

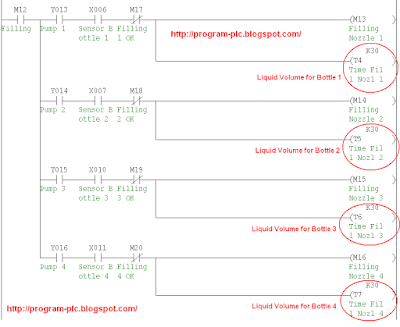

e. If M12 = ON And Y013 = ON And X006 = ON And M17 = OFF Then M13 = ON And T4 Activated ( Can be Setting for Liquid Volume ).

f. If M12 = ON And T4 = ON Then SET M17 = Hold ON ( Bottle 1 = FULL ).

g. If M17 = ON And M18 = ON And M19 = ON And M20 = ON Then M21 = ON ( ALL Bottle = FULL ).

See Picture for Setting Liquid Volume for Bottle 1 until 4 :

Step 4 :

Nozzle Up

a. If M10 = ON Or M22 = ON Then M17 = OFF And M18 = OFF And M19 = OFF And M20 = OFF.

b. If M12 = ON And M21 = ON And M23 = OFF Then M22 = ON (Latching ON).

Step 5 :

Running Screw Conveyor

a. If ( M22 = ON Or M27 = ON ) And X022 = ON And M24 = OFF Then M23 = ON (Latching ON).

b. If Y000 = ON Then C10 Activated Count Up to 4 ( Not Set ).

c. If C10 = ON Then M24 = OFF.

d. Continue To Step 3

Step 6 :

Return to Origin

a. If M33 = ON And X022 = OFF Or ( X006 = OFF And X007 = OFF And X010 = OFF And X011 = OFF ) Then M25 = ON (Latching ON).

b. Nozzle move to Up

c. If Bottle Empty Then Running Screw Conveyor

Please Download Programming for GX Developer :

Ladder PLC Mitsubishi for Filling Machine

See : PLC for Filling Machine

INPUT PLC :

X000 ; Push Button Start

X001 ; Push Button Stop

X002 ; Selector Switch 1

X003 ; Selector Switch 2

X004 ; Selector Switch 3

X005 ; Selector Switch 4

X006 ; Sensor Bottle 1

X007 ; Sensor Bottle 2

X010 ; Sensor Bottle 3

X011 ; Sensor Bottle 4

X012 ; Digital Flow Switch 1

X013 ; Digital Flow Switch 2

X014 ; Digital Flow Switch 3

X015 ; Digital Flow Switch 4

X016 ; Proximity for Count Revolution

X017 ; Fluid Sensor

X020 ; Motor Feedback Alarm for Screw Conveyor

X021 ; Limit Switch (LS) Nozzle Down

X022 ; Limit Switch (LS) Nozzle Up

OUTPUT PLC :

Y000 ; Motor ( Motor Running ) for Screw Conveyor

Y001 ; Solenoid for Cylinder Nozzle Up

Y002 ; Solenoid for Cylinder Nozzle Down

Y003 ; Single Solenoid for Drain Nozzle 1

Y004 ; Single Solenoid for Drain Nozzle 2

Y005 ; Single Solenoid for Drain Nozzle 3

Y006 ; Single Solenoid for Drain Nozzle 4

Y007 ; Single Solenoid for Filling Nozzle 1

Y010 ; Single Solenoid for Filling Nozzle 2

Y011 ; Single Solenoid for Filling Nozzle 3

Y012 ; Single Solenoid for Filling Nozzle 4

Y013 ; Single Solenoid for Pneumatic Pump 1

Y014 ; Single Solenoid for Pneumatic Pump 1

Y015 ; Single Solenoid for Pneumatic Pump 1

Y016 ; Single Solenoid for Pneumatic Pump 1

PLC Mitsubishi Programming for Filling Machine

Reading Ladder PLC Programming for Filling Machine :

Step 1 :

a.If X000 = ON And X001 = OFF And X017 = ON And X020 = ON Then M32 = ON And M33 = Momentary ON ( Pulse ).

b.M33 For Return To Origin Signal

c.If M32 = ON Then ALL System Ready ( Master Control M100 = ON ).

Step 2 :

For Pump ON and Drain Process for 1 Nozzle, Example Nozzle 1

a. If X002 = ON And M48 = OFF Then M0 = ON.

b. If Y013 = ON And Y007 = OFF Then M4 = ON.

c. If Y013 = ON And Y003 = ON And X012 = OFF Then T0 Activated ( Can be Setting for Stability ).

d. If T0 = ON Then SET M48 = Hold ON.

e. If X002 = OFF Then RST M48 = OFF.

See Picture for Setting Stability Flow Switch OFF :

Step 3 :

Filling Process

a. If (Y013 = ON And X006 = ON) Or (Y014 = ON And X007= ON) Or (Y015 = ON And X010= ON) Or (Y016= ON And X011= ON) Then M8 = ON.

b. If M8 = ON And X022 = ON And Y000 = OFF And M25 = OFF Then M9 = ON (Latching ON) And M10 = Momentary ON ( Pulse).

c. If M10 = ON And M22 = OFF And M9 = ON Then M11 = ON (Latching ON).

d. If M11 = ON And X021 = ON And M22 = OFF And M9 = ON Then M12 = ON (Latching ON).

e. If M12 = ON And Y013 = ON And X006 = ON And M17 = OFF Then M13 = ON And T4 Activated ( Can be Setting for Liquid Volume ).

f. If M12 = ON And T4 = ON Then SET M17 = Hold ON ( Bottle 1 = FULL ).

g. If M17 = ON And M18 = ON And M19 = ON And M20 = ON Then M21 = ON ( ALL Bottle = FULL ).

See Picture for Setting Liquid Volume for Bottle 1 until 4 :

Step 4 :

Nozzle Up

a. If M10 = ON Or M22 = ON Then M17 = OFF And M18 = OFF And M19 = OFF And M20 = OFF.

b. If M12 = ON And M21 = ON And M23 = OFF Then M22 = ON (Latching ON).

Step 5 :

Running Screw Conveyor

a. If ( M22 = ON Or M27 = ON ) And X022 = ON And M24 = OFF Then M23 = ON (Latching ON).

b. If Y000 = ON Then C10 Activated Count Up to 4 ( Not Set ).

c. If C10 = ON Then M24 = OFF.

d. Continue To Step 3

Step 6 :

Return to Origin

a. If M33 = ON And X022 = OFF Or ( X006 = OFF And X007 = OFF And X010 = OFF And X011 = OFF ) Then M25 = ON (Latching ON).

b. Nozzle move to Up

c. If Bottle Empty Then Running Screw Conveyor

Ladder PLC Mitsubishi for Filling Machine

See : PLC for Filling Machine