This product is the latest output from Allen Bradley. Level can use to industrial medium and large scale. Even today Rockwell Automation has made equivalent PlantPAX system is even able to compete with the reliability DCS using the ControlLogix as the main constituent component. Software used to design, download, and upload programs that RSLogix5000. It is better you know how to calibrate the ControlLogix Analog I/O Modules to ensure the best performance control system. This guidance as below:

-10 ... 10V

0 ... 5V

0 ... 10V

0 ... 20 mA

Calibrating an Input Module and an Output Module Process

There are two things you have to do for ControlLogix calibration process,: the calibration module for analog input modules and output modules. The important difference of those calibration process are:- The calibration process input modules using the parameters of current, voltage, or ohms calibrators.

- The calibration process output module using the tools of digital multimeter (DMM) to measure the signal modules sent. The position signal is sent to the outside of the module. This process requires calibration instruments with specific ranges as recommended in the table list the calibration module.

How can we calibrate with Either Program or Run Mode?

The calibration process can be carried out outside the standard program RSLogix5000. You can use other programs on the condition that you must connect online and using precision resistors. One of the recommended resistors is KRL Electronics - 534A1-1R0T a 0.01% 1.0 Ohm / 487 Ohm 534A1-487R0T a 0.01%. Do not use components that are below standard, for example 1756-IF16 module with a voltage calibrator of greater than +/- 150 μV accuracy). This is to avoid the occurrence of errors and anomalies.Modules Input calibration process

Input calibration process module needs to be done to ensure that the accuracy of data input can be processed properly. The process is relatively complex because it includes three main parameters that require specific calibration range. The process includes:- The process of calibrating the 1756-IF16 or 1756-IF8 Modules

- The process of calibrating the 1756-IR6I Modules

- The process of calibrating the 1756-IT6I or 1756-IT6I2 Modules

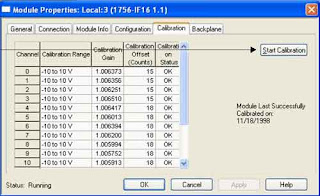

Calibrating the 1756-IF16 or 1756-IF8 Modules

The calibration process begins with the 1756-IF16 or 1756-IF8 modules. This calibration is used in applications requiring voltage or current by using a four-parameter input voltage ranges:-10 ... 10V

0 ... 5V

0 ... 10V

0 ... 20 mA