The ABB AC500 PLC is designed for reliable and robust control system and has the advantage of the scalable, cost-effective and flexible automation solutions. This PLC is suitable for designing and implementing the appropriate configuration for simple control tasks or complex automation solutions consisting of various CPU, I / O modules, communication modules, communication interface module and accessories.

PLC capability is supported by large memory, fast network performance, advanced visualization, operating convenience with some specifications support device as follows:

Some simple applications such as solar trackers, high volume production of circuit breakers, large ships, tunnel automation, traffics control, packaging, printing machines, and robotics are using this PLC.

There are various connection options that can support the performance of the system from the connection center using I Local / O bus CPU module, the connection of up to ten I / O modules that can be connected to the CPU and connection outskirts of decentralization through fieldbus between the CPU module and remote I / O module. To get the most number of modules must meet various requirements, such as AI531 with 8 different types of signals in one module.

PLC capability is supported by large memory, fast network performance, advanced visualization, operating convenience with some specifications support device as follows:

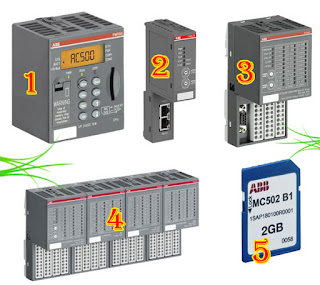

1. CPUs

CPU AC500 is designed with the concept of using single integrated software to meet the demands of a new control system that is easy, safe and reliable. The AC500 PLC is designed with sufficient memory capacity and has a variety of communication possibilities, onboard which can be integrated into various combinations, forming large network nodes from the smallest to the largest automation solutions.Some simple applications such as solar trackers, high volume production of circuit breakers, large ships, tunnel automation, traffics control, packaging, printing machines, and robotics are using this PLC.

2. Communication Modules

Communication modules become an important key data access speed of PLC. AC500 has the ability to combine up to four communication interface integrated CPU with additional (up to) four slots for communication modules to support data access speed supported by communication standards and protocols such as Ethernet, EtherCAT, PROFINET, PROFIBUS DP, CANopen, DeviceNet, Modbus TCP, Modbus RTU, RCOM, ABB CS31. This module allows communication to control and level the playing field and can be integrated into various combinations.3. Communication Interface Modules

Interface module into a device supporting this communication with developing and implementing a wide range of connectivity options for remote I / Os. AC500 PLC offers a range of connectivity options for remote I / Os. The interface modules provide more functions such as fast tables and additional configurable I / Os form a large network nodes from the smallest to the largest automation solutions.4. S500 I/O Modules

S500 module I / O has the ability to handle multitask such as software configurable I / O modules and provides a variety of basic I / O modules with different channel, a voltage signal and fieldbus connection.There are various connection options that can support the performance of the system from the connection center using I Local / O bus CPU module, the connection of up to ten I / O modules that can be connected to the CPU and connection outskirts of decentralization through fieldbus between the CPU module and remote I / O module. To get the most number of modules must meet various requirements, such as AI531 with 8 different types of signals in one module.