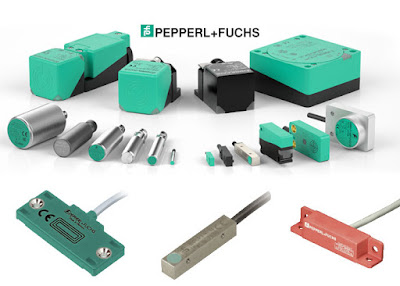

Proximity sensor is the kind of sensor that has the function to detect the presence of objects without physical contact. It is known that the proximity sensors control the highest level of durability, quality, and redundancy of the objects. This proximity sensor is to meet the challenging needs of the industry these days. You can choose a wide range of sensors up close to meet all kinds of applications.

Image by https://www.pepperl-fuchs.us

The process of proximity sensor includes applications for the positioning, inspection, detection, sorting machines and also automated manufacturing systems. It is also used in these devices: production, packaging, plastic mold, metal, printing, and food industries, and many others.

This is the kind of non-contact proximity sensor that can detect a target of iron, ideally mild steel thicker than one millimeter. It uses four main components: the oscillators, nucleus of ferrite with cabbage, the amplifier output of sound and Schmitt trigger.

This kind of sensor is driven by permanent magnet. It has working principle that is according to the use of communications reeds. This sensor consists of two low magnetic reluctance cement reeds enclosed in glass bulbs that contain an inert gas.

The process of proximity sensor includes applications for the positioning, inspection, detection, sorting machines and also automated manufacturing systems. It is also used in these devices: production, packaging, plastic mold, metal, printing, and food industries, and many others.

The Type of Proximity Sensor

In this review, we will share and explain about these three types of proximity sensor, those are:1. Capacitive Sensor

Capacitive sensor can be used to detect metal objects and the other materials like metal. These sensors are used for some applications including flow control and level for the detection of pills, powders and liquids. This sensor has the ability to perceive through non-ferrous materials. Hence, this is ideal tool for monitoring the glass scene, recognition of the level of powder hopper and the detection level of the liquid reservoir.2. Inductive Sensors

Inductive proximity sensors can be used for most applications that need precise detection, non-contact metal objects in machinery or automation equipment. You can find high quality and innovative inductive sensor to meet. Standard inductive sensor product features include: Smooth or threaded steel housing, a reflection of the polarization and short circuit protection, like regard, including M8, M12 or connect peripheral models, LED indication status and the models with PVC, PUR or silicon cable.This is the kind of non-contact proximity sensor that can detect a target of iron, ideally mild steel thicker than one millimeter. It uses four main components: the oscillators, nucleus of ferrite with cabbage, the amplifier output of sound and Schmitt trigger.

3. Magnetic field sensor

It consists of our choosing magnetic field sensor and also the other supporting device of this Magnetic field sensor was widely used with combination of steel hydraulic cylinders. This magnetic sensors provide reliable detection of magnetic piston and easy to install, without the need for installation of slots or holes in the cylinder.This kind of sensor is driven by permanent magnet. It has working principle that is according to the use of communications reeds. This sensor consists of two low magnetic reluctance cement reeds enclosed in glass bulbs that contain an inert gas.