Video about snack vending machine for one type of product. This use Game Control for Simulation of Snack Vending Machine. See the video for How to work of Snack Vending Machine Simulation.

Free Download for Snack Vending Machine Simulation for One type of product:

(This file on Google Docs, for download: click File and click Download)

1. Download for Windows x86(XP): click here

2. Download for Windowsx64 (WIN7): click here

3. Download for Mac: click here

4. Download for Linux: click here

Image about Insert Coin of Snack Vending Machine Simulation.

Image about take snack after snack vending machine finish process.

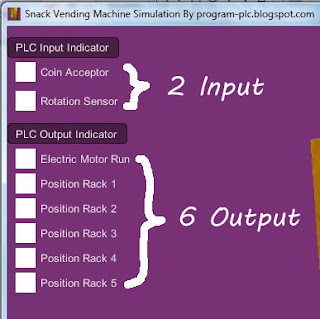

A. PLC Input and PLC Output

This application use PLC Controller for drive / controller of Snack Vending Machine. And Input / Output needed by the PLC for Snack Vending Application:

A1. PLC Input :

[Input0] One Input for receiving signal from Coin Acceptor.

[Input1]One Input for receiving signal from the Rotation Sensor, example: Proximity Sensor or etc.

A2. PLC Output :

[Output0] One Output to Drive an Electric Motor Run.

[Output1] One Output to Switch Position Rack 1.

[Output2] One Output to Switch Position Rack 2.

[Output3] One Output to Switch Position Rack 3.

[Output4] One Output to Switch Position Rack 4.

[Output5] One Output to Switch Position Rack 5.

Thus, the input and output requirements for Snack Vending Machine Application are: 2 Input and 6 Output of PLC input / output modules.

See the image for PLC Input Indicator and PLC Output Indicator:

B. Electrical Wiring of Snack Vending Machine for One type of product

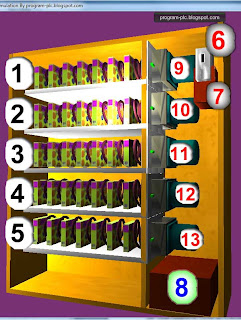

B1. Detail of Snack Vending Machine

1. Position Rack 1

2. Position Rack 2

3. Position Rack 3

4. Position Rack 4

5. Position Rack 5

6. Coin Acceptor

7. Coin Box

8. PLC Box or Panel Control Box

9. Electric Motor for Rack 1

10. Electric Motor for Rack 2

11. Electric Motor for Rack 3

12. Electric Motor for Rack 4

13. Electric Motor for Rack 5

14. Rotation Sensor / Proximity Sensor for Rack 1

15. Rotation Sensor / Proximity Sensor for Rack 2

16. Rotation Sensor / Proximity Sensor for Rack 3

17. Rotation Sensor / Proximity Sensor for Rack 4

18. Rotation Sensor / Proximity Sensor for Rack 5

B2. Electrical Wiring of Snack Vending Machine

1. PLC Wiring Diagram

2. Motor Control and Relay wiring diagram for each Rack without speed control motor

3. Motor Control and Relay wiring diagram for each Rack with speed control motor

Example Coin Acceptor :

http://www.adafruit.com/category/35_104

Example Rotation Sensor / Proximity Sensor :

http://program-plc.blogspot.com/2009/06/equipments-of-input-for-plc.html

http://program-plc.blogspot.com/2009/06/example-of-input-wiring-diagram-plc.html

Example Relay or Contactor :

http://program-plc.blogspot.com/2009/06/equipments-output-plc-system.html

http://program-plc.blogspot.com/2009/06/training-wiring-diagram-output-plc.html

Example Speed Control Motor :

http://program-plc.blogspot.com/2009/10/speed-control-motor-to-plc.html

C. Sequences PLC Programming for Snack Vending Machine for One type of product

1. Number of products per rack = 7 pieces snack

2. Number of Racks = 5 racks

3. Total of all products = 7 x 5 = 35 pieces snack

4. Use PLC Counter (Total Products) to enter the Total of all products.

5. Setting PLC Counter with 35 for start value (full snack).

6. Use PLC Counter to count the coins from the Coin Acceptor signal [Input0].

7. Switch Rack Position and Rotation Sensor:

7.1.Rack 1 (Relay R1 [Output1]) only ON, If PLC Counter (Coins) greater than zeroand value PLC Counter (Total Products) between 29 and 35.

7.2. Rack 2 (Relay R2 [Output2]) only ON, If PLC Counter (Coins) greater than zero and value PLC Counter (Total Products) between 22 and 28.

7.3. Rack 3 (Relay R3 [Output3]) only ON, If PLC Counter (Coins) greater than zero and value PLC Counter (Total Products) between 15 and 21.

7.4. Rack 4 (Relay R4 [Output4]) only ON, If PLC Counter (Coins) greater than zeroand value PLC Counter (Total Products) between 8 and 14.

7.5. Rack 5 (Relay R5 [Output5]) only ON, If PLC Counter (Coins) greater than zeroand value PLC Counter (Total Products) between 1 and 7.

See the table below with PLC Counter (Coins) greater than zero:

8. Use PLC Counter to count the Rotation Sensor [Input1]

9. If PLC Counter (Coins) greater than zero (pulse up) then reset to zero of PLC Counter (Rotation Sensor).

9.1. For one full rotation, then the value of PLC Counter (Rotation Sensor) equal to two.

9.2. One Full Rotation equal to One Coin or One Piece Snack

9.3. If PLC Counter (Rotation Sensor) equal to two :

9.3.a. Decrease PLC Counter (Total Products) by one

9.3.b. Decrease PLC Counter (Coins) by one

9.3.c. Reset to zero of PLC Counter (Rotation Sensor)

10. If Relay R0 [Output0] is ON, then PLC Counter (Coins) greater than zero and one of R1 [Output1] to R5 [Output5] is ON

11. If PLC Counter (Coins) is zero, then Relay R0 [Output0] is OFF and all R1 [Output1] to R5 [Output5] is OFF.

Note:

Application about Snack Vending Machine for One type of product use 3 PLC Counter:

1. Total Products use Memory and use Increment/Decrease Operation

2. Count the Coins use Memory and use Increment/Decrease Operation

3. One PLC Counter for Count the Rotation Sensor

Can You Make PLC Program for This Application?

If can’t:

PLC Programming for Snack Vending Machine