Simulation :

Example Results Marking By Laser Engraving Machine :

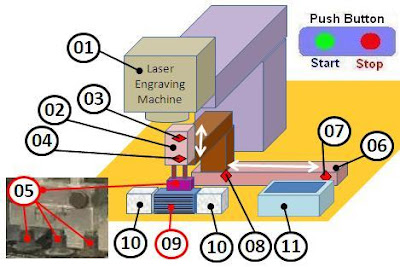

Information on Drawing Numbers for Detail Marking with Laser Engraving Machine :

1. Laser Engraving Machine

2. Cylinder to Up - Down for Pneumatic Vacuum Cups

3. Limit Switch Up for Pneumatic Vacuum Cups

4. Limit Switch Down for Pneumatic Vacuum Cups

5. Pneumatic Vacuum Cups

6. Cylinder to Reverse - Forward for Vacuum Cups

7. Limit Switch Reverse for Vacuum Cups

8. Limit Switch Forward for Vacuum Cups

9. Plate Structure or Workpiece

10. Magazine for Plate Structure or Workpiece

11. Finished Workpiece Basket

Number Of Inputs and Output PLC applied :

1. Number Of Inputs PLC is 10 Input :

--- 1 Unit Input for Push Button Start.

--- 1 Unit Input for Push Button Stop.

--- 2 Unit Input for Limit Switch ( LS ) Up - Down for Pneumatic Vacuum Cups.

--- 2 Unit Input for Limit Switch ( LS ) Reverse - Forward for Vacuum Cups.

Example Input from Laser Engraving Machine :

--- 1 Unit Input for Ready From Laser Engraving Machine.

--- 1 Unit Input for Error From Laser Engraving Machine.

--- 1 Unit Input for Marking From Laser Engraving Machine.

--- 1 Unit Input for Marking Complete From Laser Engraving Machine.

--- Total Number Of Inputs PLC is Minimum 10 Input Unit.

2. Number Of Output PLC is 9 Output :

--- 1 Unit Output for Solenoid to Pneumatic Vacuum Generator.

--- 2 Unit Output for Solenoid to Up - Down for Pneumatic Vacuum Cups.

--- 2 Unit Output for Solenoid to Reverse - Forward for Vacuum Cups.

Example Output from Laser Engraving Machine :

--- 1 Unit Output for Emergency Stop To Laser Engraving Machine.

--- 1 Unit Output for Marking Start To Laser Engraving Machine.

--- 1 Unit Output for Count-Up To Laser Engraving Machine.

--- 1 Unit Output for Counter Reset To Laser Engraving Machine.

--- Total Number Of Outputs PLC is Minimum 9 Output Unit.

Sequence PLC Programming for Marking with Laser Engraving Machine :

Step 1 :

a. If Push Button Start = ON Then Emergency Stop To Laser Engraving Machine = ON (Hold ON).

b. If Emergency Stop To Laser Engraving Machine = ON And Ready = ON And Error = OFF And LS Up Vacuum Cups = ON And LS Reverse Vacuum Cups = ON Then Counter Reset To Laser Engraving Machine = Pulse ON ( With Timer ) And Counter PLC = 0 And Marking Start To Laser Engraving Machine = ON.

c. If Marking = ON Then Marking Start = OFF.

d. If Marking Complete = ON Then Next to Step 2.

Step 2 :

a. If Marking Complete From Laser Engraving Machine = ON Then Solenoid Forward for Vacuum Cups = ON.

b. If LS Forward for Vacuum Cups = ON Then Solenoid Down for Vacuum Cups = ON.

c. If LS Down for Vacuum Cups = ON Then Solenoid to Pneumatic Vacuum Generator = ON And Timer Vacuum Activated .

d. If Timer Vacuum Cups = ON Then Solenoid Up for Vacuum Cups = ON .

e. If LS Up for Vacuum Cups = ON Then Solenoid Reverse for Vacuum Cups = ON .

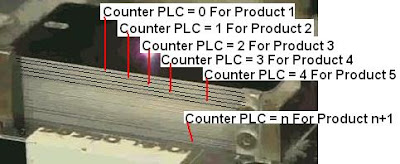

f. If LS Reverse for Vacuum Cups = ON Then Solenoid to Pneumatic Vacuum Generator = OFF And Count-Up To Laser Engraving Machine = ON And Counter PLC Increased by one.

g. If Counter PLC = OFF ( Current Value <> 5 ( Be Changed )) And Emergency Stop To Laser Engraving Machine = ON And Ready = ON And Error = OFF Then Marking Start To Laser Engraving Machine = ON.

h. If Marking From Laser Engraving Machine = ON Then Marking Start = OFF And Goto Step 2.a.

i. If Counter PLC = ON ( Current Value = 5 ( Be Changed ) for 5 Product ) Then Process Marking Stop.

Download Simulation Process :

Marking with Laser Engraving Machine

Step 3 :

a. If Push Button Stop = ON Or Error From Laser Engraving Machine = ON Or Ready From Laser Engraving Machine = OFF Then Process Marking Stop.

Can You make Program Ladder PLC ?

If Can't :

PLC Omron Programming for Marking with Laser Engraving Machine

PLC Mitsubishi Programming for Marking with Laser Engraving Machine

PLC Keyence Programming for Marking with Laser Engraving Machine