What is a PLC?

A Programmable Logic Controller, or PLC, or also called Programmable Controller is a specialized-computer to control device or equipment in industry. The National Electrical Manufacturing Association (NEMA) defines a programmable controller a digital electronic apparatus with a programmable memory forstoring instructions to implement specific functions, such as logic, sequencing, timing, counting,and arithmetic to control machines and processes.Why use PLC?

Traditional industrial control system use wire to connect devices directly each otherbased on how the system supposed to work. In PLC, the wiring procedure is replaced as soft-wiring. It’s similar as build virtual wiring by using a control program. Soft-wiring makes changes in control system easy and cheap than traditional one. Other advantages of using PLC include: high reliability, small space requirements, computing capabilities, reduced costs, ability to withstand harsh environments, and expandability.What does a PLC consist of?

PLC consist of processor unit, power supply, input/output (I/O) interfaces, and programming device. Processor unit, like in computer, is the brain and decision-maker of PLC. It is based on microprocessorsystem which can perform arithmetic function, data manipulation, and communication between I/O sections.Power supply is the section that provide suitable voltage and current to operate. Usually, it convert 120 or 240 volts AC voltages to the low DC voltage required by processor and I/O modules.

The input/output interfaces consist of input modules and output modules. The number of input and output modules depend on requirement and PLC specification. In new type PLC, the I/O modules can be modular. User can add the number of I/O as their requirement to be controlled by PLC. In old type it is fixed based on manufacture specification. The real input (I) devices can be push buttons, analog sensors, pressure switches, selector switches, etc., while the output (O) devices can be hardwired motor starter coils, solenoid valves, indicator lights, positioning valves, etc.

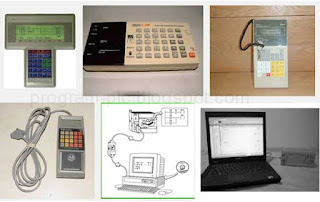

The programming device is an equipment used to enter desired program to PLC memory. The program is usually enter using relay ladder logic or other programming language of PLC. There are two type of programming device, hand-held and personal computer. A hand-held is specialized devicededicated to program PLC independently. In old days it most used by engineer that need to customized PLC program on site. But today a personal computer is most used to program PLC’s on the market.

What the difference between PLC and computer?

There some similarity between PLC and computer. The twos have internal memory for its operation and storage of the program. But, PLC is designed to operate by plant or maintenance engineer with limited knowledge of computer and don’t need high skilled of computer operation. PLC typically programmed using relay ladder logic, unlike PC (Personal Computer) that programmed using high level and sophisticate programming language. Although PLC can be programmed by other form of PLC language, such as Structured Text, Sequential Function Chart, and Function Block, but it still simple than PC language. Today, most PC is used to programming and monitoring the PLC.The real differences also can be seen from hardware specification. PLC is based on microcontroller while computer based on microprocessor. PLC can store program and data, but in a tiny size than computer. PLC data and program that can be stored is about 2MB-4MB in general and stored in EEPROM media. While PC today can stored program and data in huge size inside hard drive. Minimally a PC have 80 GB hard drive today. It is not impossible to replace PLC function with PC. It can work as PLC does, but CPU lack in stability and costly than PLC.

Control Program

Control program is the software orprogram that inputted by user using programming device and store in PLC’s memory. Control program consist of fragment called instruction. Instruction is computer code that make input and output do what the user want as the result. PLC have two types of instruction. There are contact and coil type. Contact is instruction that refer to input condition. Coil is instruction that refer to the output condition. Contact type will monitor its input condition, then if something changed, it tell the program to do as the designer want. In other hand, the coil type will monitor the output and tell the program to do something when the output status has changed. The process of monitoring input, execute program, and change the output status is called scan.Programming Device

Programming device is an instrument used to enter desired program or software that build by designer into PLC memory. There are two types of programming device, hand-held and personal computer (PC). Hand-held is dedicated programming tools for PLC. It is looks like a calculator with strange button and symbols, but today, PC is the most used programming device.

Labels:

PLC Articles

PLC Articles